EVOX_SPEED3

Member

Is this even an option for our cars. I would be happy with some lowering springs, and a front anti-sway bar. I know it's not as good as coilovers, but it would be much cheaper.

Is this even an option for our cars. I would be happy with some lowering springs, and a front anti-sway bar. I know it's not as good as coilovers, but it would be much cheaper.

Maybe I'm full of crap, but it feels to me like the front isn't too bad, but the rear sucks big time. I'm kinda wondering if a rear sway bar would do the job by itself, but don't know if that would cause other problems similar to SteveSonic's post on under steer.

I remember how the early VW Rabbits would "lift a leg" (the inside rear wheel, parenthetically to piss on a hydrant) when pushed during autocross. It was perfectly normal for that chassis to do that and the Rabbits would often win their class. I'd guess today that the cars were set up with cut or otherwise high rate rear springs, and not rear anti-roll bars, as a fix for FWD understeer. An anti-roll bar will pull down the inside wheel of the loaded axle.

As a previous owner of Rabbits and current owner of Sciroccos (same platform), I can say that they have bigger rear anti-sway bars than front anti-sway bars. That's not totally the reason they tend to hike the inside rear wheel though. They also have a torsion beam rear axle which is extremely similar to the Sonic's. That design is basically a sway bar itself. As the outside wheel/suspension is compressed the inside wheel is lifted. Since the car is also leaning, the inside wheel tends to come off the ground.

I will bet that, at an autocross, a Sonic will lift its inside wheel just like 90% of front wheel drive cars.

I was doing some research today for work and stumbled upon the "contribution of rall rate" spec for the Sonic axle. The spec is checked/measured with the axle mounted in a fixture (at the bushings just like it mounts in the car) and one arm held solid. The free arm is then pushed down at the location where the spindle/bearing assembly is attached. The spec is it must take 450Nm +/- 25 to move the free arm 4.55 degrees. Unfortunately, it is in degrees so there is not an easy linear conversion to translate this into a common wheel rate measurement such as lbs/in.

98.9 newton-meters per degree = 72.96 foot-pounds per degree

From your description, the Saab 9-3 sounds similar to the old Rabbits. It took me a while to find a decent photo, but here is what a rear sway bar for an old Rabbit looks like (thanks Google images):

The blocks/saddles are on the horizontal portion of the axle and the ends mount to the shock bolts. Since the axle already works like a sway bar, mounting the bar directly to it is not a problem. You are effectively "supplementing" its existing roll stiffness. This is basically how I was going to do it on the Sonic. Because of the exhaust, shape of the floor pan, etc., it would be very difficult to mount the horizontal portion of the bar to the body. Another possible design is a nested straight bar that gets bolted or welded into the beam itself.

I'm just trying to wrap my head around your bar setup on the Sonett. I got that the arms are attached via links to the chassis. What is the center/horizontal portion of the bar mounted to?

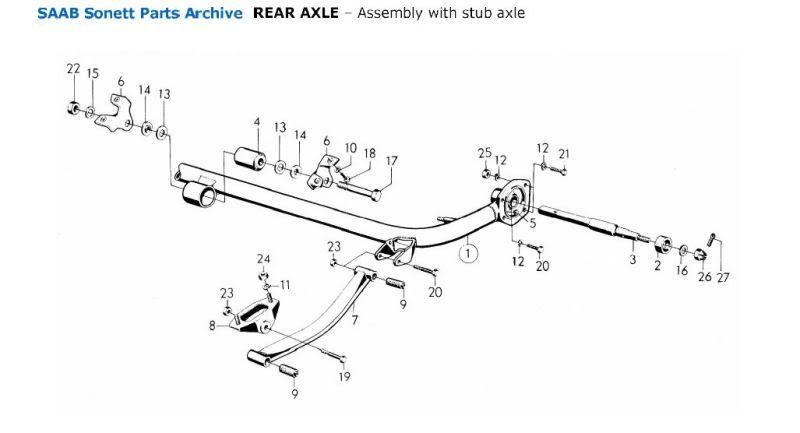

Is this what your rear suspension looks like?